We Are Trusted By Our Customers

Project composition:

Car industry

Support BMW going electric: Lead Intelligent signed the PACK intelligent production line of BMW

Project introduction

In 2021, Lead Intelligent signed a cooperation agreement with BMW to provide it with the overall solution of PACK intelligent production line of new energy cars. This cooperation is not only an important milestone in the internationalization of Lead automotive intelligent production line business, but also the crystallization of the trend of Lead digital manufacturing technology and the electrification of cars.

This project is a key project planned by BMW in 2020. Since the beginning of the year 2020, BMW has been communicating with the Lead Intelligent. Lead Intelligent responded to the needs of customers actively, and conducted in-depth technical exchanges with customers by means of VR, remote video interaction and online technical collaboration during the first half of year 2020 despite the inconvenience caused by gloabal epidemic. The strong technical strength of Lead Intelligent has won high recognition from BMW.

In the end, Lead Intelligent stands out among global competitors and provide the overall solution of PACK intelligent production line for BMW. In addition to meeting BMW's high quality standards, the PACK production line has made technological breakthroughs in the aspects of high production flexibility, rapid scalability, simulation intelligence and security. Lead Intelligent has been comprehensively affirmed by BMW.

"The cooperation between Lead Intelligent and BMW is a high-level technical communication!" President Yanqing Wong commented, "We have been cooperating with European customers for many times. BMW's high recognition, once again proved our technology and product strength."

In the face of global pioneering problems, the technical team of Lead Intelligent gives full play to its technology and experience in equipment design and manufacturing, as well as the accumulation of M&E, software, simulation, engineering and other fields. Lead Intelligent works closely with BMW team for several months, communicating in English as well as German, keeping pace with customers on the other continent, providing BMW with complete solutions, in which a number of technological innovations achieved breakthroughs.

The innovative design of WPC can achieve ergonomics and flexible production.

In order to meet the customer's demand for flexible production of multiple products and the technical standards of ergonomics in the production, Lead Intelligent innovated and developed a patent: synchronous turnover WPC. This not only solved the ergonomic problem, but also innovatively combined the turnover process with the transfer process, which greatly improved the working efficiency of the working station.

5G transmission technology promotes intelligent manufacturing of production lines

In order to meet the needs of intelligent and digital production in the workshop on the subject of transmission media between workshops, Lead Intelligent demonstrated a variety of transportation modes to the customers and innovatively proposed AGV intelligent logistics solutions based on 5G network communication technology. At the same time, with rich experience in 5G application scenarios, Lead Intelligent has demonstrated the stability and possibility of 5G technology in the field of automotive PACK to customers and won recognition.

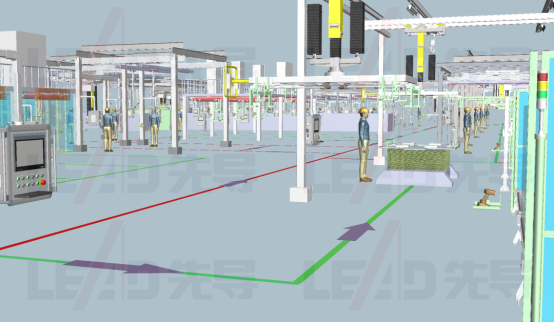

“Digital twin technology” improves production line manufacturing efficiency

Digital factory is an important direction of future automobile production line. The technical team of Lead Intelligent uses “digital twin technology” to build virtual production line, and completes ergonomic simulation, structural engineering simulation, operational accessibility simulation, virtual commissioning of production line, etc. This is expected to result in a 15%-25% optimization of the project duration. At the same time, “digital twin technology” will continue to contribute to the customer's production and marketing efficiency and cost reduction in the operation process of future production line.

Production line safety can promote car electrification safety.

Safety is a key link in the development of the car electrification trend. From the perspective of customers, Lead Intelligent provides a turnkey solution from the aspects of production line layout planning, structural safety design, production line operation and maintenance experience, emergency management, etc., to meet their safety needs for the production line and relieve their worries. The safety design of the PACK intelligent production line will help to improve the quality of PACK products, thus ensuring the safety of electric cars.

Advantages of the project:

The implementation of the scheduling system is based on PLC platform and ST language, which is designed for indutrial scenes and focusing on security.

AGV compatible with QR code and ribbon navigation can achieve seamless switching

AGV steering wheel structure can achieve any direction of the AGV travel.